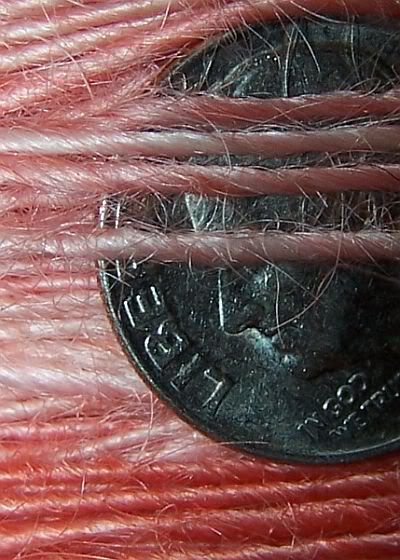

So, I have been spending the evenings, and sometimes the early morning hours, spinning my flax. I have a long way to go, and much practice ahead of me, before I can spin smooth, without slub or knot. The more I work with it, the more I am amazed at how much it seems like I am spinning hair. In the picture above, my hair is to the far left...with the flax being at the bottom. Just looking at the flax ~it resembles hair, but when I am spinning it wet, it often makes the squeaky clean sound...the same sound that my hair makes whilst I am rinsing it after a good shampoo.

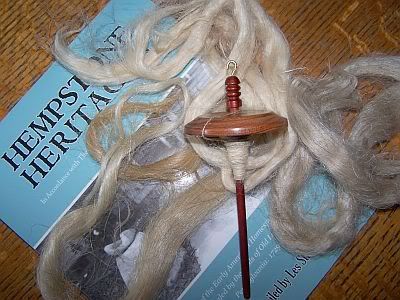

I think if I dress the distaff carefully, I can spin better. I don't have a "real distaff", but I am using a branch from a white pine in the meantime.

To dress the distaff with the flax, I simply laid the flax out onto the table, and spread it thin, then laid the distaff on top of it. Next, I wound the flax, pulling it from time to time, to tighten it around the distaff.

Once it was wound onto the distaff, I put it into the distaff holder on the Ashford Traditional, and pulled the flax from the bottom down, to begin drafting. It was a bit awkward for me, as I am accustomed to drafting with my right hand, and holding the twist with my left. I also used a small water pot to wet the flax, but my fingers soon became very cold.

My great grandmother spun flax. I have never seen what she looked like. I wished I could ask her to show me how to handle it correctly. I wished I could sit next to her and watch her spin. I thought a lot about her while I was spinning.

I have been reading as much as I can, about the flax and the hemp.

I find it to be very interesting research. One publication that I came across, by Richard Hall, was printed in 1724, and discusses the different methods used in cultivating and processing flax and hemp in Holland and Ireland.

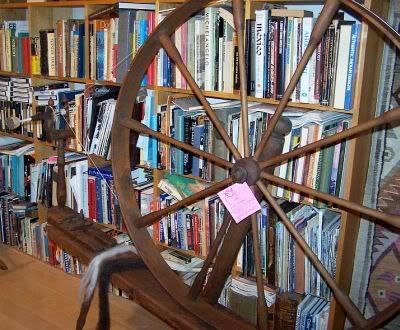

I found out that the Great Wheel was used to spin hemp in Ireland....I also learned that the Hemp spinners made quite a bit more $$ than those who could spin flax. A good Hemp spinner was hard to find and could produce 15 to 18 pounds of hemp fiber a day!! I am amazed at that quantity. I also marvel at the ability. I wonder about the length of the fibers, because to see the old photographs of the hemp growing in the fields, the plant towers above the heads of the working men.

Another discovery (in the same publication) was the reference made to Hemp Mills. There were 4 of them in Ireland at the time of the publication. The sail cloth factories depended on the Hemp Mills. The tow hurds were spun from the butt ends of the hemp, and it was used for warping yarn to weave the sails. The fimble hemp (or those plants that bore no seed and were longer) were used for the weft of the sail cloth. The carl hemp (that bore the seed), was shorter and was spun for twine for fishing, sailmakers thread or bedcords and packing twine.

I really got to thinking about those spinsters. How hard they must have worked, how many hours they must have spent with their wheels! What masters they must have been! Imagine being the spinner who had to produce the knot free hemp yarn that would be woven into sailcloth, knowing that if you let a slub or a knot slip by, it would compromise the skins of the canvas- that if strained by the wind, would run into holes!

And today, most of us spin for fun. How far we have come....or have we?

So, what did I do with this small bit of first flax? The tomatoes needed tying up, and it worked just fine!