It is getting hard to find a good supplier of flax strick. Good quality flax strick should be bundled, with all of the flax measuring the full length of the plant. Generally, it is 30 to 36 inches in length. This full length is important when it comes to dressing a line distaff for spinning. A line distaff is for long line flax strick, or an uncut full length.

The image above contains an example of premium quality flax strick on the left, and poorer quality on the right. The color of the flax would indicate the retting method. But if you examine the photo, you might notice that the flax on the left is nicely prepared, and the fibers are not stuck together. There are no pieces of broken boon (or the woody outer waste portion of the flax stem). I had ordered this flax strick online, and when it arrived I was disappointed in the quality. I really should have sent it back. I can send it through the hackels and clean it, or scutch and swingle it..but a fair amount will be wasted, and I paid for line flax, not tow.

I am posting these two videos of flax processing for you to compare (for those that might be interested). One video shows the modern methods and the other shows the traditional methods. One thing that strikes me when I compare the two videos, is that in the traditional or old method of processing --the flax is handled by human hands a good deal of the time.

Do you think we have a finer product by means of the new methods, or the old?

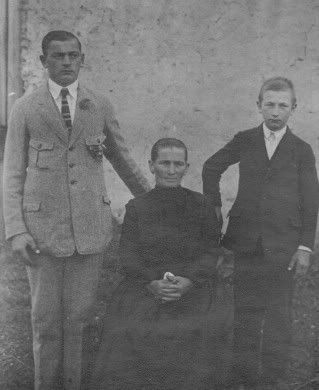

I would like to wish everyone a Happy Mothers Day...and show you a photo of my Great-grandmother, whose hands planted, processed, and spun flax to linen...long ago, and far away.

Having now completed the process with my homegrown/handspun flax... I feel a sort of bond or a sense of sisterhood with her...and certainly a sense of appreciation for the skill and work involved in creating a good piece of linen.

9 comments:

I've spent the last hour or so with your post...which I must say was one of your usually best yet! I enjoyed the video's and have a greater respect for the people that toil the soil for the natural fibers...Your great grandmother would be very proud of you indeed..I almost hear her saying "you go girl":o)...Ginny

I think its lovely that you have followed your ancestor's footsteps and going through all the processes of making linen. I bet she would have been proud. Its nice to have that connection with family, even if you don't get to connect with them in person.

Awww....thank you Ginny....I would love to hear my great-grandmothers voice! I wonder what she sounded like....oh my...I wouldn't be able to understand a word, she spoke a language that is lost in time because of wars.....

Sharon, one of the reasons I became so interested in trying to grow and rett my own flax was because of my great-grandmother!

I thought of her quite a bit throughout the process...wishing she could whisper in my ear, and tell me how to do it!

This was just fascinating. I had no idea how much was involved with flax production. Wow. Thanks so much for sharing. I'll have much more appreciation next time I have the opportunity to spin some. There is a very old flax wheel at my parents house, but no one remembers who used it :-/.

I noticed some flax in a booth at Maryland Sheep and Wool and I remember thinking as I passed "That's not right" but didn't really go into it in my head. Now I can see exactly what bothered me about it!

Processing of flax is so interesting. I have to admit that it's one fiber I've never spun. Yet. But it is on my "someday" list.

Lovely post.

I think another photo would be most appreciated, too.

But maybe that's just me ;-)

One of these days, I need to spin flax again! I think all I have is tow, however. I hope you didn't buy the crappy stuff from the woman I told you about, many moons ago, on Rav!

Post a Comment